MO-82

The Combined Use of a Stepping Motor and an Oil Hydraulic Drive Enables the Accurate Positioning of a Microelectrode.

Used in combination with the DM System, the MO-8, MO-10 Pencil-type Micromanipulator which is easily mountable onto a mechanical manipulator or stereotaxic instrument, ensures even more accurate drive control. The Motor Drive incorporates a 5-phase stepping motor that enables higher precision of fine movement operation. With the working distance of 10mm, the insertion of a microelectrode can be achieved without unwanted vibration.

The Adoption of Multi-slot CardBus Reader Allows Additional Drive Units

Based on the DM System, control boards are expandable thus up to three Drive Units can be controlled by one Control Box and one Keypad Controller.

Your existing 2-phase stepping motor driven manipulator (MO-81, SM-21, MO-951, etc.) can be connected by the use of a CardBus (sold separately).

The Adoption of Multi-slot CardBus Reader Allows Additional Drive Units

Based on the DM System, control boards are expandable thus up to three Drive Units can be controlled by one Control Box and one Keypad Controller.

Your existing 2-phase stepping motor driven manipulator (MO-81, SM-21, MO-951, etc.) can be connected by the use of a CardBus (sold separately).

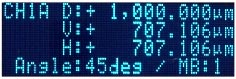

Equipped with Diverse Functions to Support Various Experiments

Three driving modes: Free Drive/Set Drive/Step Drive are user-selectable and the respective minimum movement units are user-definable.

Equipped with Diverse Functions to Support Various Experiments

Easy-to-operate sheet keys are used for the Keypad Controller.

USB Communications Interface

USB communications interface enables remote-control operation, permitting automatic drive to a specified position as well as interfacing to external hosts such as PCs through application programs.

Communications protocol available upon request. By downloading the firmware update through your PC, you will be able to utilize the most up-to-date features.

Specifications

Accessories (included)

Dedicated Electrode Holder, Keypad Cable, Display Cable, Extension Cable for Display, AC Power Cord, Rack Mount Brackets, Bracket Mounting Screws, Rubber Foot

Length of hydraulic tubing

1.5 m

Drive source

5-phase Stepping Motor

Movement range

10 mm

I/O port for communication

USB Type B

Power source

AC 100 V - 240 V, 50/60 Hz

Power consumption

50 W

Dimensions/ Weight

Drive Module W 30 × D 20 × H 125 mm, 50 g

Motor Drive W 97 × D 31 × H 56 mm, approx. 0.25 kg

Control Box W 430 × D 350 × H 80 mm, 8.2 kg

Keypad (Controller) W 125 × D 142 × H 30 mm, 0.28 kg

Display W 140 × D 85 × H 35 mm, 0.26 kg